Rocket

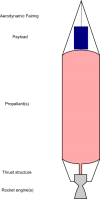

A rocket is a machine which ejects mass for generating velocity. Typical elements of a rocket are propulsion systems, propellant utilization systems, structures, guidance and control and tanks. A rocket does not need to be its own spacecraft. It can be made for space or as part of a larger spacecraft system.

Propulsion systems

A rocket gains velocity by ejecting mass through a rocket engine. The concept is plain conservation of impulse (or Newtons third law). Every second, the rocket ejects propellant mass through the nozzle of the rocket engine. The impulse of this mass is compensated with the remaining rocket accelerating. The more mass getting ejected (This property is called mass flow) or the faster this mass gets ejected (called average exhaust velocity or specific impulse), the more velocity the rocket gains.

The primary way to accelerate the exhaust is to use chemical energy: The propellants get combusted at high pressures inside the engine to generate heat. A rocket is thus also often called a "controlled explosion". And a typical rocket is because of that, almost only propellant tanks and rocket engines.

Rocket engines have usually so called convergent-divergent nozzles: A small throat area followed by a bell-shaped or cone shape nozzle extension. The nozzle is one of the most critical parts of a rocket, as it has the job to accelerate the exhaust. The shape of the nozzle depends on the many parameters, of which for most fantasy rockets only two relations might be interesting:

- The higher the chamber pressure a rocket engine, the smaller can be the nozzle for the same thrust.

- The ratio of the throat area and the exit area of the nozzle (the so called expansion ratio) depends on the ambient pressure (for example sea level or vacuum). The smaller the expansion ratio, the lower is the effect of ambient pressure, meaning the rocket engine is more effective on lower altitudes. That's why boosters usually have short nozzles and upper stages which operate in vacuum, even get moving extensions to make the nozzles longer.

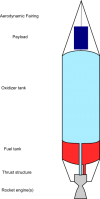

Bipropellant rockets

A bipropellant rocket is a rocket, which uses two liquid or gasous chemicals for propulsion. One component is called typically fuel, the other oxidizer (even when it, in the case of Flour, does not contain oxygen). The propellant combinations of bipropellant rockets are further classified by the storage temperatures, toxicity and ignition behavior. Propellants which require cooling below -50°C to stay liquid are called cryogen. They can only get filled into the rocket tanks shortly before launch and can't stay liquid for long once inside the tanks. The amount of propellants, which turn to gaseous form and need to be vented outside the tanks is called boil-off.

A common problem of all liquid fueled rockets are the movements of the liquid propellants inside the tanks, called sloshing. It requires careful design of the tank walls to increase the resistance and also has to be considered inside the control loop design.

Typical fuel combinations are liquid hydrogen and oxygen (called hydrolox) and kerosine plus liquid oxygen (kerolox).

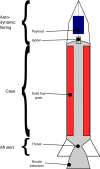

Solid rocket

A solid rocket or solid rocket motor stores all the propellants in solid form inside the combustion chamber. Their advantage is, that, once ignited, they don't shutdown. They are also very simple in design and construction and can deliver very high thrust. Their main disadvantage are their low specific impulse.

Once ignited, thrust can only be terminated by thrust termination devices, which for example lower the chamber pressure below the threshold required for sustaining combustion. This is usually destructive.